As the cannabis industry continues to expand, cultivators and processors are constantly seeking innovative solutions to optimize their operations and deliver top-tier products to consumers. One area that has seen remarkable evolution is post-harvest processing equipment.

From traditional hand processing methods to the advent of machinery, the industry has experienced a significant shift towards favoring automation. For commercial producers in particular, maintaining quality and consistency while achieving high volumes can be difficult if the workflow is not scaled properly.

Early Methods of Cannabis Processing and Hand Trimming

In the early days of cannabis cultivation, processing the harvest was a long and labor-intensive task. Cultivators would meticulously buck, trim, and sort flower by hand, relying on their personal expertise to achieve desirable results. While this approach was sufficient for the early era of cannabis processing, it would prove to be difficult to scale as operations expanded.

Processing a cannabis harvest by hand is time-consuming, costly, and highly susceptible to inconsistencies with the products. As the industry grew, it became clear that a more efficient solution was necessary to meet the increasing demand for high-quality cannabis products.

The Rise of Early Cannabis Processing Machines

The first iterations of cannabis processing machines emerged as a response to the limitations of manual labor. Sourcing workers to manually process a harvest is difficult due to the seasonality of the work, risks with personnel, and inconsistencies with processing. In addition, manual processing takes significantly longer than machines.

These early machines, although rudimentary compared to more current technologies, represented a big leap forward in efficiency. Cannabis buckers, for example, automated the tedious task of removing buds from the stems, reducing processing time significantly. Although imperfect, these early machines laid the groundwork for further advancements in equipment to come.

The Shift to Modern Technologies

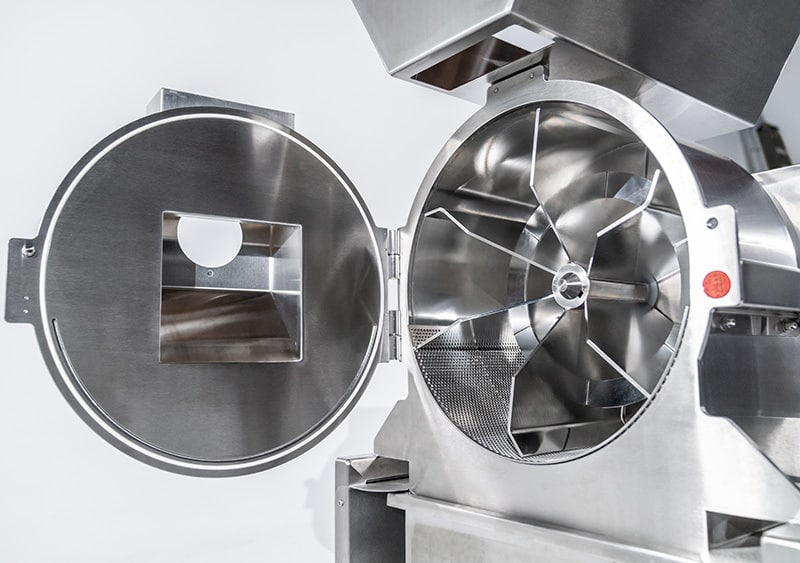

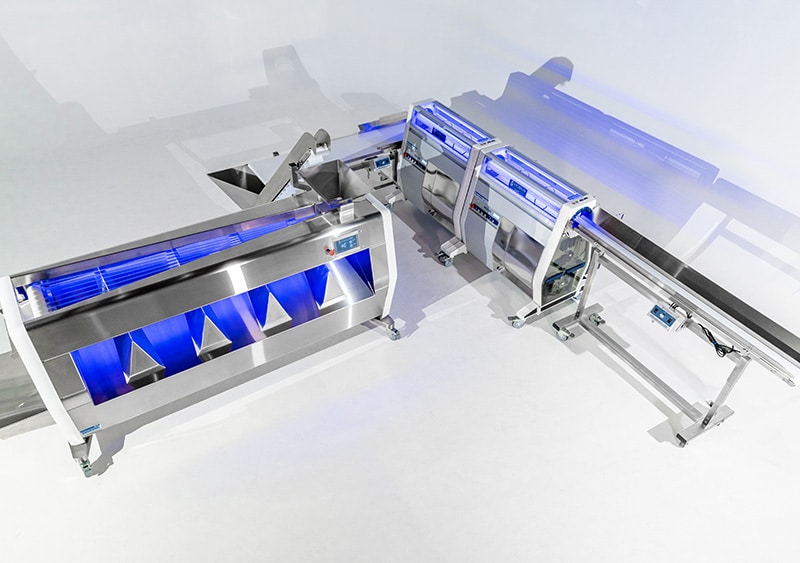

After a few iterations of processing equipment, the industry was introduced to highly sophisticated machines for post-harvest cannabis automation. This modern equipment like the Mobius Automation Suite combines cutting-edge technology with a scalable operation, allowing cultivators to find the workflow that best suits their needs. The Mobius Automation Suite provides unparalleled efficiency and quality control, with multiple checkpoints throughout the processing line. The Automation Suite includes machine trimmers, buckers, sorters, mills, and conveyors to connect it all together.

Machine processing has numerous benefits, allowing for faster processing times, better product quality, and more consistent results than hand processing. Because automation eliminates the reliance on manual work, cultivators reduce labor and operating costs, which also frees up personnel for other tasks. Additionally, these machines can process large quantities of flower quickly, accelerating production cycles and improving overall productivity.

The evolution of cannabis processing equipment from traditional hand methods to modern automation has been a game-changer for the industry. Growers and processors now have access to efficient, reliable, and consistent solutions that maximize productivity and quality. As the industry continues to evolve, the integration of cutting-edge equipment like the Mobius Automation Suite ensures that growers and processors stay at the forefront of innovation, delivering exceptional cannabis products to an ever-growing market.

End