The team at Greenventory keeps calibrating their inventory control tool for more automation to help cannabis companies meet operational and compliance challenges head-on instead of circumventing them.

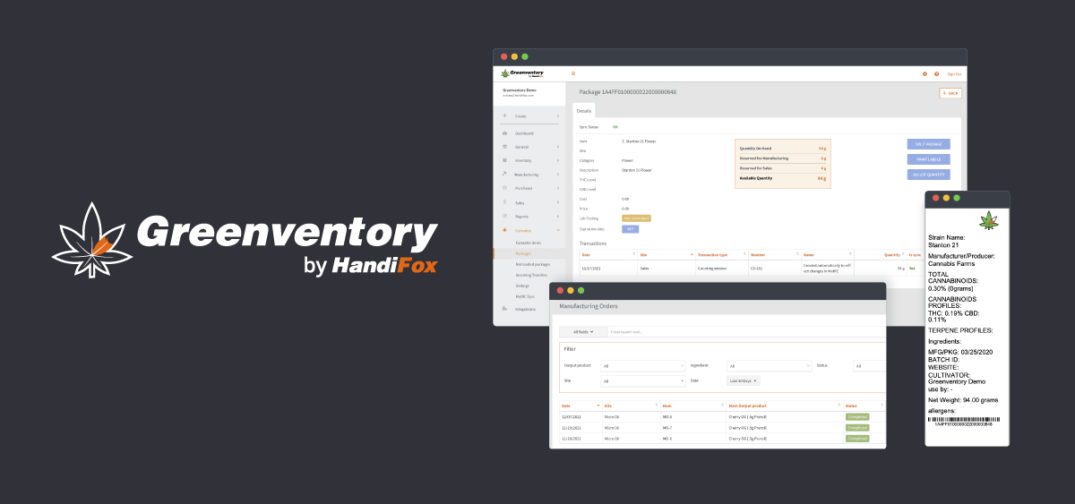

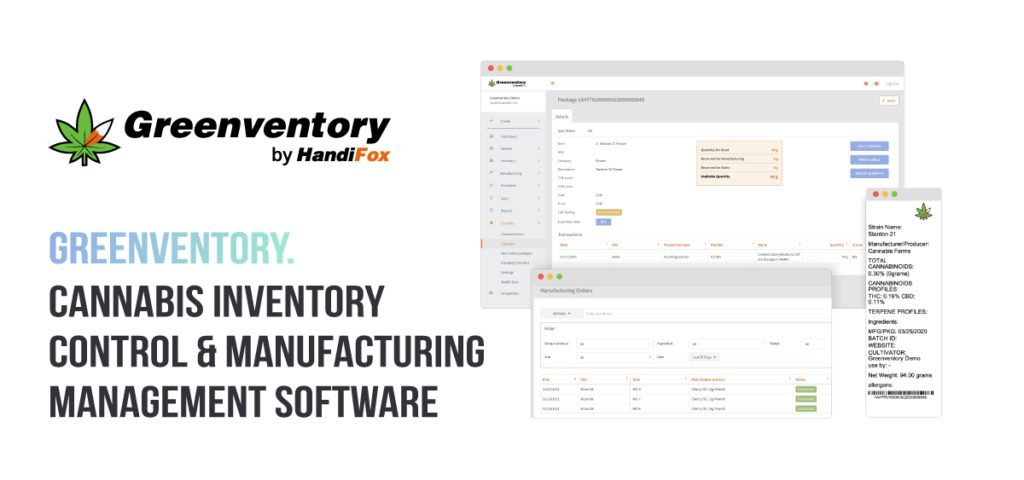

Melbourne, Florida – Greenventory, Metrc-integrated cannabis inventory control & manufacturing management software built by Tecom Group, Inc., has been recently updated with more advanced manufacturing functionality to further bolster the work of cannabis processing and distribution companies.

With ever-evolving regulatory requirements, staying operational, compliant, and profitable comes with a lot of hurdles. Greenventory attempts to minimize the number of hoops to jump through by automating the task of documenting production processes and sending compliance reports into Metrc.

Businesses in the manufacturing vertical are baffled by the ongoing challenge of maintaining optimal inventory levels, documenting production, fulfilling customer orders, and getting compliance data over to the track-and-trace system on top of that. Greenventory’s manufacturing module allows creating presets (recipes) that can be used in manufacturing orders and, when applied, cause the software to predict manufacturing capacity based on components’ availability. As soon as manufacturing orders are completed in Greenventory, Metrc gets updated on new stock on hand (newly produced items) and the quantity changes for respective component items.

Along with the extended manufacturing functions, Greenventory offers a toolkit of other features that open up automation opportunities in areas like inventory tracking, purchasing, order fulfillment, sales, and accounting to help cannabis manufacturers, distributors or those with a microbusiness license face the uncertainties of the industry with greater operational resilience.

The software tracks and provides real-time quantity on hand information for cannabis and non-cannabis products across multiple storage locations. Greenventory users are encouraged to barcode their inventory early on and are able to print compliant product labels with a company logo, a barcode, and all relevant information pertaining to the product.

To bring extra speed and accuracy, Greenventory has baked barcoding into all possible workflows – looking up a stock item, stock intakes, inventory counting, adding line items to Purchase, Sales Orders, and Invoices, picking and packing customer orders before shipment.

Cannabis operators are challenged to perform repackaging (splitting the content of one package into several or combining multiple packages into one) in a way that keeps Metrc in the loop and inventory records intact. Splitting or merging packages in Greenventory will result in the emergence of new packages with new IDs. The software makes sure that the traceability data such as new package ID, changes to inventory levels, and closed packages will be broadcast to Metrc immediately.

Greenventory supports the work with suppliers through automated purchase order management and a barcode-driven receiving process that helps catch shipping errors and validate received products before they get accepted in Metrc.

Cannabis businesses looking to align their accounting with everyday operations can opt for Greenventory’s bi-directional QuickBooks integration. The software can be set to push inventory, purchasing, and sales data to the accounting system based on a schedule.

Sign up for a free trial at https://app.greenventory.handifox.online/Account/Register or email ruslan@greenventory.online.

End