Controlled Environment and Data-Driven Results Equals Consistent Harvests and Increased Potency

Consistency is one of the most important markers of a successful cannabis harvest, but it’s a fickle factor that can seem impossible to control. As cultivators know all too well, Mother Nature often has her way: Even the slightest environmental or atmospheric change can trigger dramatically different phytocannabinoid and terpene yields, which can result in a tarnished brand reputation and disappointed customers.

For one Agrify client, cultivating reliable and consistent quality cannabis was key to growth and continued success in a competitive market. However, traditional grow room operations could not minimize the inconsistencies from harvest to harvest. This cultivator turned to our Vertical Farming Units (VFUs) and our fully integrated software platform, Agrify Insights, to standardize each harvest. Here’s why — and how — our solutions worked for them.

Why consistency matters in cannabis cultivation

Consumers have more options than ever before as more states legalize cannabis for medical or adult use. As the market matures, competition increases: With dozens of options at the dispensary, brands need to work harder to capture the hearts and minds of customers, whether they are adult-use consumers looking to relax or medical cannabis patients who rely on a specific brand or cultivar for healing. Consistency is key to that: Consumers expect the same product quality from every other product they buy — why not cannabis?

The same goes for a cultivator’s business partners. A cannabis company needs to know that their supplier is capable of producing a consistent and a reliable product. Without the same or similar phytocannabinoid and terpene profiles, a brand may risk its reputation as a quality purveyor of cannabis flower, losing customers to competitors who can produce that reliable experience with each session. Therefore, it’s in the cultivator’s best interest to recreate the same results time and again.

Challenges cultivators face when trying to achieve consistency

First and foremost, cannabis is a plant, and variances are bound to occur as a plant grows. Changes relative to humidity, temperature, light, soil, water, and other factors impact the final product’s phytocannabinoid content and terpene content. Precisely which factor is the “secret ingredient” that gives a particular cultivar its THC content, scent, or terpene profile is a tough metric to track. Once the ideal conditions are discovered and optimized, they need to be put back into a grow operation’s procedures and standards. That can be impossible to achieve without software that offers granular insights into a grow operation.

Cultivators need the right tools to control atmospheric variability better.

Many traditional vertical racks and other grow equipment are open systems that do not protect the plants from risks at the grow room level. Without containing each harvest or using software to detect changes, growers cannot directly control environmental factors that shape the final product. These racks either need to be retrofitted with a third-party sensor system or carefully monitored individually. Both processes are prone to human error and still do not resolve the potential risks at play by being a part of a larger echochamber.

These factors only get more challenging to control as cultivation facilities scale up, expand, or make other changes to their standard operating procedures (SOPs). Cannabis is so sensitive to its growing conditions that even different rooms within the same facility can significantly change the harvest’s phytocannabinoid and terpene content.

The best option a cultivator has at their disposal is an enclosed integrated grow solution that can precisely control climate while tracking and analyzing data collected from each grow. That solution can be found through Agrify.

How Agrify Vertical Farming Units and Agrify Insights™ help ensure consistency

Agrify Vertical Farming Units (VFUs) and Agrify Insights operate as two sides of the same coin. These two robust solutions arrive at the facility already integrated, providing an unparalleled controlled environment that can be carefully monitored and adjusted for optimal results.

Each Agrify Vertical Farming Unit features a fully enclosed and managed micro-climate, complete with grow lights and intercanopy lights; automated irrigation and CO2 delivery; built-in temperature controls; and motorized curtains for photoperiod control. This tightly controlled environment means that the cultivar’s compound profile will stay at the same or similar levels when each VFU is programmed to the same settings, no matter where in the facility they’re placed. A different cultivar can grow in each unit without interfering with other cultivars’ progress or outcome in nearby VFUs.

Agrify Insights grow room automation software allows cultivators to plan their operations from A to Z. This software tracks and analyzes the data needed — 800,000+ data points annually, per VFU — for reliable and consistent harvests. This information can then be applied back to future harvests, standardizing the results each time. Agrify Insights allows for a birds-eye view of all statistics, or get granular and dive deep into any number of environmental factors, including temperature, relative humidity, and irrigation plans.

Because Agrify Insights arrives fully integrated with each vertical farming unit, there are no sensors to outfit or additional products to purchase. All hardware and software needed to standardize and optimize each harvest is ready to go from the onset. Agrify works with our customers to help customize each facility’s grow plans that can be programmed right into the software, to achieve our client’s goals.

Agrify at work: Cultivar consistency by the numbers

Our client, a commercial cannabis cultivator in North America, needed a solution that would allow them to more efficiently and reliably produce the same or similar results for each cultivar in each harvest. By taking a more calculated approach to their cultivation processes, our client knew they could produce distinguished and distinct cannabis flower in a crowded legal cannabis market.

Agrify grow solutions provided the data and transparency needed to fine-tune their grow processes for the desired final product, while self-contained VFUs enabled precise environmental control, unlike any other solution they used. The company outfitted their entire operation with VFUs equipped with Agrify Insights, with the first harvest occurring in late 2020.

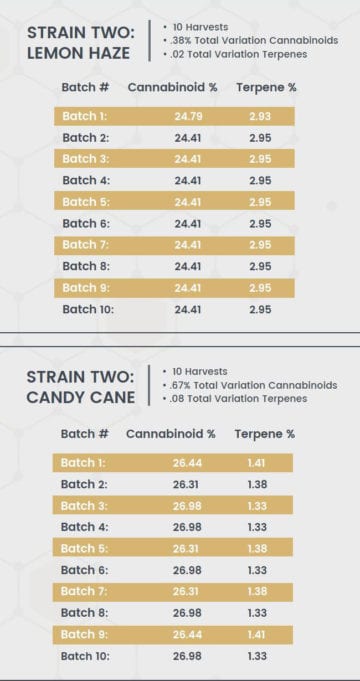

The results spoke for themselves: Each grow produced only slight differences between each harvest of the same cultivar. An analysis of 10 Lemon Haze harvests found just a .38% variation on phytocannabinoid content and a .02% variation on terpene content. Another cultivar, Candy Cane, yielded a .08% variation in total terpenes and just .67% variation in total phytocannabinoid content across 10 harvests. Before Agrify grow solutions were introduced into their facility, the variability in cannabinoid and terpene percentages prevented them from confidently producing branded products.

The overall yield was impressive, too. After implementing Agrify cannabis grow solutions, this cultivator achieved .717 pounds per square foot per year for the first time. The overall phytocannabinoid and terpene content were eye-opening: The cultivator measured a whopping 34% total phytocannabinoid content and more than 3.75% total terpenes. For comparison, high phytocannabinoid content is generally considered to be at around 21% or higher, while terpene content typically tops out around 2%.”

Cannabinoid and terpene results by strain

Conclusion

As the legal cannabis industry grows and new brands are introduced into the marketplace, yield consistency can help a cultivator stand out to customers and business partners alike. This Agrify client realized the only way to constantly produce the same results was to apply data back into a tightly controlled process, achievable through our VFUs and Agrify Insights software. Within just a few months, our clients saw the lab reports returned with remarkably similar phytocannabinoid and terpene percentages, proof that this careful planning, monitoring, and fine-tuning is just what’s needed for product quality and reliability each and every harvest.

Click to learn more about Agrify grow solutions, or contact us for more information at sales@agrify.com

End